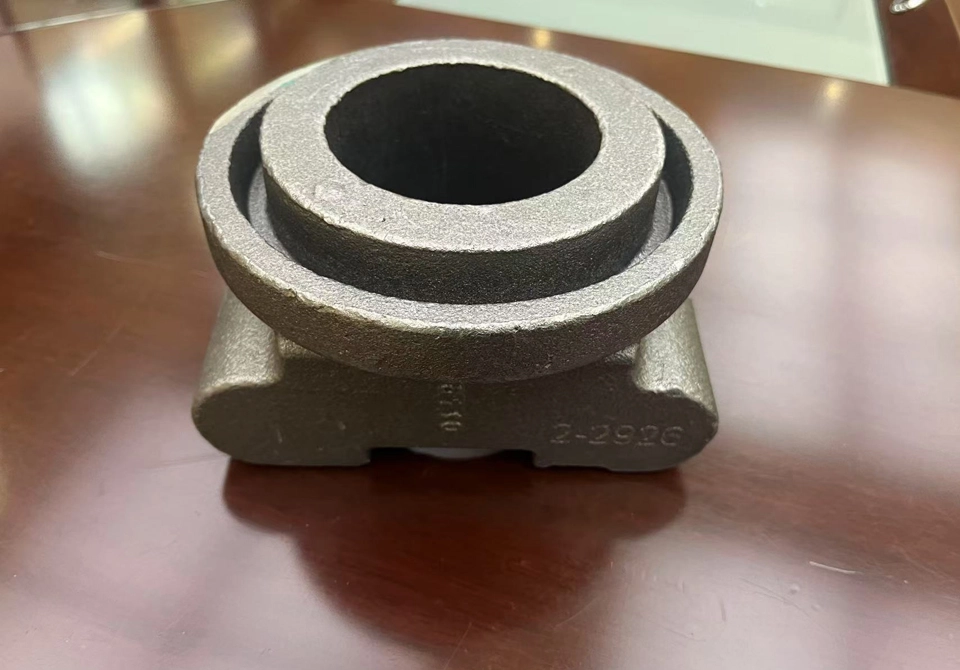

Balasen can undertake various engineering machinery industry components, not limited to engine components (such as cylinder blocks, cylinder heads, flywheels, etc.), working device components (such as buckets, boom arms, etc.), chassis components (such as track shoes, drive wheels, support wheels, etc.), hydraulic system components (such as hydraulic motors, hydraulic cylinder blocks, multi way valves, etc.).

Hardness Requirements:

The hardness of engineering machinery castings usually needs to meet certain standards. For example, the hardness range of gray cast iron is generally Brinell hardness HB 100-220, and after quenching treatment, the hardness can reach Rockwell hardness HRC 48.

Tensile Strength and Elongation:

The tensile strength and elongation of castings are also important quality indicators. For example, the empirical relationship between the tensile strength and hardness of gray cast iron is: when σb ≥ 196 N/mm², HB = RH(100 + 0.438σb); when σb ≥ 796 N/mm², HB = RH(44 + 0.724σb).

Chemical Composition Requirements:

The chemical composition of castings has an important impact on their performance. For example, ductile iron castings need to meet specific chemical composition requirements, including the contents of elements such as carbon, silicon, manganese, phosphorus, and sulfur.

Metallographic Structure Requirements:

The metallographic structure of castings has a direct impact on their mechanical properties. The requirements for the metallographic structure are specified in detail in the standard to ensure that the castings exhibit good performance during use.

Dimensional Tolerance and Machining Allowance Requirements:

There are also specific requirements for the dimensional tolerance and machining allowance of castings to ensure the accuracy and reliability of the castings during assembly and use.

Surface Quality Requirements:

The surface quality of castings has an important impact on their service life and appearance. The requirements for surface quality are specified in the standard, including defects that are not allowed, such as air holes, sand holes, and shrinkage cavities.

Material innovation:

New alloy materials are developed and applied to improve the strength, toughness, wear resistance and corrosion resistance of castings. For example, the addition of rare earth elements to cast iron can refine the microstructure and improve its mechanical properties.

Process innovation:

Advanced casting processes such as precision casting and vacuum casting are adopted to improve the dimensional accuracy and surface quality of castings, reduce internal defects, and enhance the overall performance.

Structure optimization:

The structure of castings is optimized through computer-aided design (CAD) and finite element analysis (FEA) to make the stress distribution more reasonable, improve the bearing capacity and service life of castings.

Heat treatment innovation:

New heat treatment processes and technologies are used to improve the internal organization and performance of castings. For example, the application of induction heat treatment can improve the surface hardness and wear resistance of castings.

The materials include the following:

Carbon steel:

ASTM A148: 90-60, 120-95;

ASTM A216: WCB, WCC;

ASTM A352: LCB, LCC, LC2, LC3;

EN10213: 1.0619, 1.6220;

RCC-M M1112: 20MN5M, 20M5M;

Alloy steel

ASTM A217: WC5, WC6, WC9, C5, C12, C12A, CA15;

ASTM A487: 4C,4D,9D;

EN10213: 1.7357, 1.7379;

Stainless steel

ASTM A351: CF3, CF8, CF3M, CF8M, CF8C, CF10M, CN7M, CG3M, CG8M, CN3MN, CK3MCuN;

ASTM A747: CB7Cu-1;

EN10213: 1.4308, 1.4408, 1.4581;

RCC-M M3402: Z3CND19-10M, Z3CN20-09M;

Duplex Stainless Steel

ASTM ASTM A890/A995: 5A/CE3MN, 6A/CD3MWCu, 4A/CD3MN, 1B/CD4MCuN

Nickel Alloy

ASTM A494: M35-1, CU5MCuC, CW6MC, CW12MW, CY40, N7M, N12MV, CW2M, CW6M, CX2MW, Hastelloy, Monel Alloy, Cornell Alloy