Green sand casting is a traditional process widely used in metal casting. Its core involves mixing clay as a binder with sand particles to create sand molds for pouring molten metal. Below is a detailed summary of its key parameters, advantages, classifications, and suitable products.

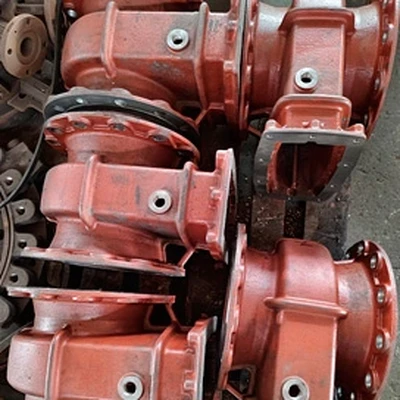

We have an automatic production line for horizontal tide mold sand in Dongjiu, Japan, which can provide 5-100kg ductile iron and gray iron castings, 100 boxes/hour, with an annual production capacity of over 16000 tons of castings. Mainly producing ductile iron parts (main grades QT400, QT450, QT500, QT600, QT700, etc.), including automotive parts, fire hydrant series, valve series, flange series, pipeline series, mechanical series and others, which can achieve all processes from casting to processing

Key Parameters of Green Sand Casting

1. Sand Mixture Ratio

- Clay content: Typically 8-12% (by mass), with clay serving as the binder.

- Sand particles: Mainly silica sand (80-90% by mass), with particle size controlled (50-100 mesh) to improve fluidity.

- Moisture: 4-6% (affects mold strength and permeability).

2. Green Compression Strength

- Mold compression strength: 0.1-0.3 MPa, ensuring the mold does not deform during handling and pouring.

3. Permeability

- Standard value: 80-150 (permeability units), ensuring gases are smoothly discharged during pouring.

4. Compactness Rate

- 35-45%, reflecting the degree of mold compaction, which affects strength and surface quality.

5. Mold Hardness

- Green sand hardness: 70-90 (Shore hardness scale), requiring uniform compaction.

1. Cost-effective

Low material cost: Natural sand and clay are abundant and inexpensive, reducing procurement expenses.

Minimal equipment investment: Simple equipment leads to low initial investment and maintenance costs.

Low energy consumption: No need for high-temperature baking, thus saving energy.

2. Good process performance

High molding efficiency: The sand's fluidity enables rapid filling and short molding cycles.

Relatively high accuracy: can achieve good dimensional accuracy and surface quality.

Good permeability: Allows gas to escape during pouring, reducing defects.

3. Easy operation

Simple to master: The straightforward process is easy for operators to learn.

Flexible production: Can choose manual or machine molding for different production scales.

4. Environmental-friendly

Recyclable: Used sand can be recycled, minimizing waste.

Low pollution: Emits fewer harmful substances, being environmentally friendly.

I. Post-Processing Flow for Green Sand Casting

1. Sand Knockout

- Purpose: Separate the casting from the sand mold and remove most of the adhering sand.

- Methods:

- Mechanical knockout: Using vibratory shakeout machines or tumbling equipment.

- Manual knockout: Suitable for small or complex castings.

2. Gating and Riser Removal

-Purpose: Remove the gating system (gates, risers, overflow channels, etc.) from the casting.

- Methods:

- Gas cutting, grinding wheel cutting, hammering, or hydraulic shearing.

3. Surface Cleaning

- Purpose: Remove residual sand, oxide scale, and burrs.

- Steps:

- Mechanical cleaning: Shot blasting, sand blasting, or grinding.

- Chemical cleaning: Acid pickling (to remove oxide scale) or alkaline cleaning (to neutralize residual clay).

4. Heat Treatment (Optional)

- Purpose: Improve the mechanical properties of the casting (e.g., annealing, normalizing, quenching).

- Applications: Castings requiring high precision or strength (e.g., gears, engine components).

5. Quality Inspection

- Inspection Items:

- Visual inspection: Surface cracks, pores, sand inclusions, and other defects.

- Dimensional measurement: Using calipers, coordinate measuring machines (CMM), etc.

- Non-destructive testing: X-ray, ultrasonic testing (UT), or magnetic particle testing (MT).

6. Defect Repair

- Methods:

- Welding repair (for cracks or pores).

- Epoxy resin filling (for small defects in non-load-bearing areas).

7. Anti-Corrosion Treatment

- Methods:

- Spraying anti-rust oil or paint.

- Phosphating treatment (to enhance surface corrosion resistance).

8. Packaging & Storage

- Notes: Moisture-proof, impact-resistant packaging with clear labeling.

II. Key Considerations**

1. Sand Reclamation:

- Used sand from knockout must be screened, magnetically separated (to remove metal scraps), and dedusted before reuse to reduce material costs.

2. Environmental Measures:

- Wastewater from chemical cleaning must be neutralized, and dust collection systems must be installed for shot/sand blasting equipment.

3. Automation Equipment:

- Automated shot blasting machines or robotic cutting systems are recommended to improve efficiency and consistency.

Valve Body

Valve Bonet

Body

Body

Cover

Bonet

Bonet

Please upload files like drawings, material specifications, quantities, and shipping destination.