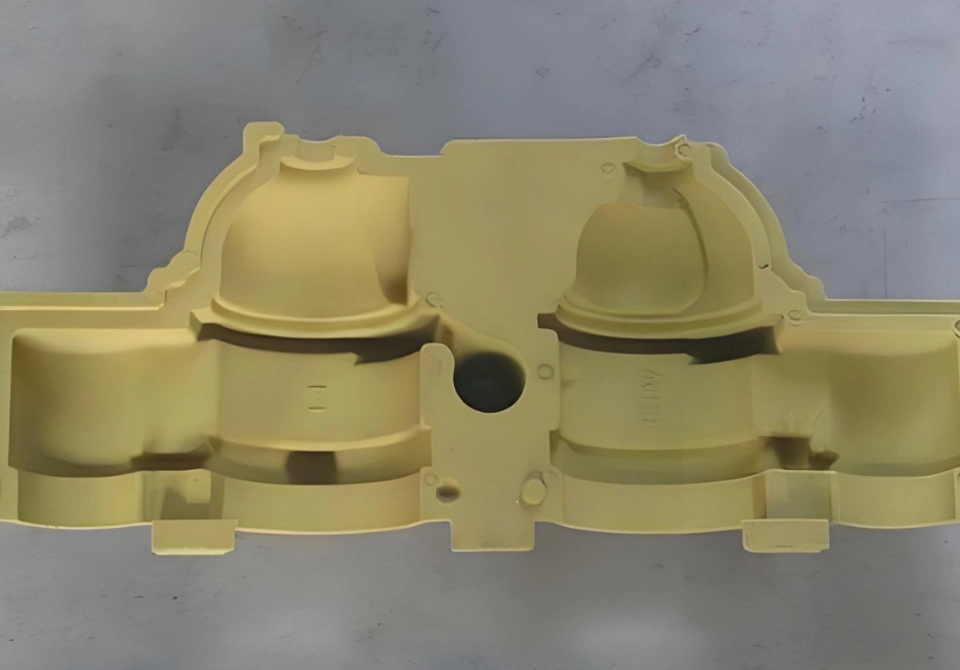

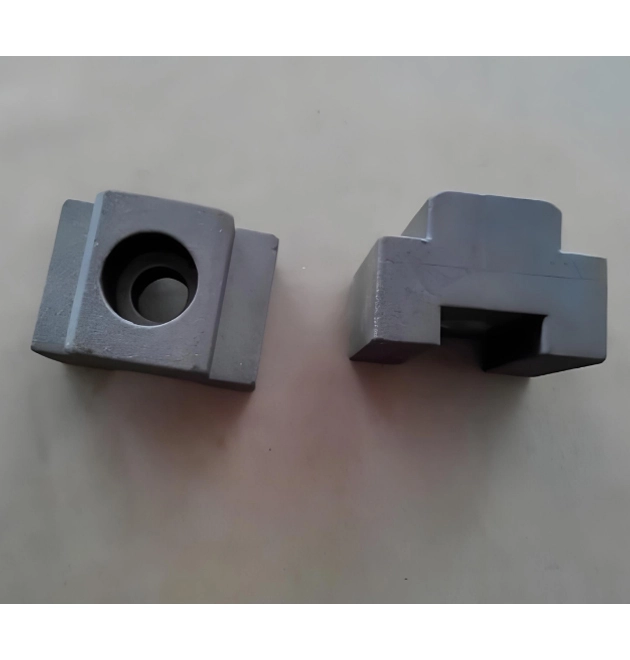

Shell Casting is an efficient precision casting process that forms thin shell molds by heating resin sand, suitable for mass production of small and medium-sized complex metal parts. Its characteristics are high mold strength, smooth surface, precise size, and the ability to cast fine or thin-walled structural parts, such as automotive camshafts, gears, pumps and valves, and hardware accessories. The advantage lies in high production efficiency, low sand consumption, and reduced machining allowance, making it suitable for materials such as carbon steel and alloy steel. Widely used in the fields of automobiles, machinery, and energy, balancing economy and quality stability, it is an important technical solution for large-scale manufacturing of precision castings.

It is a casting method that uses a mixture of high-strength thermosetting materials such as silicon sand or zirconium sand and resin to form a thin shell mold and pour it to obtain castings; Another type is sand covered iron casting: a casting process in which a thin layer of sand is covered in the inner cavity of a metal mold (known as an iron mold) to form a mold. It evolved from metal mold casting and shell mold casting, and thus combines the advantages of metal mold casting and shell mold casting, overcoming the defect of white cast structure in metal mold castings

This process method makes the surface of the casting smoother, the size more accurate, reduces or eliminates the need for mechanical processing, shortens the production cycle, saves metal materials, and reduces costs; And the mold can be made by automatic machinery, without the need for skilled workers; Especially suitable for batch and mass production of various metal small and medium-sized castings; It is usually suitable for castings with strict size requirements weighing between 1kg-50kg, and the tolerance level of castings can achieve CT 7-9 levels.

Fine coated sand:

using finer particle size (such as 70-140 mesh) coated sand to reduce sand gaps and form a dense and smooth mold cavity surface;

Mold surface treatment:

Metal molds are pre coated with high-precision release agents (such as silicon-based coatings) to ensure uniform sanding and no mold sticking defects;

Optimize solidification process:

Precisely control the heating temperature (280-320 ℃) and time of sand coating to fully melt and flow the resin, reducing the surface micropores of the sand layer;

Pouring parameter control:

Reduce the pouring temperature of the metal liquid (to avoid mold hot corrosion), use vacuum or low-pressure pouring to reduce turbulence, and suppress oxidation slag inclusion;

Preheating of the mold shell:

Before pouring, heat the mold shell to above 200 ℃ to remove residual volatiles and avoid surface roughness caused by pores;

Post processing optimization:

using shot blasting or electrolytic polishing instead of traditional sandblasting to accurately remove burrs and improve surface consistency. Through the above process optimization, a high smoothness of Ra 3.2-6.3 μ m can be achieved, meeting the requirements of precision components.

Mold preparation:

Preheat the metal mold (template) to 200-300 ℃ and apply release agent on the surface;

Film coated sand coating:

evenly cover the surface of the mold with resin film coated sand, and melt the resin at high temperature (about 300 ℃) to form a thin shell of 5-15mm;

Curing and demolding:

After cooling and hardening, the shell is pushed out, and the two halves of the shell are combined and bonded to form a complete mold;

Preparation for pouring:

Fill the shell with dry sand for reinforcement, preheat to remove residual volatiles;

Metal casting:

Molten metal (such as steel and cast iron) is injected into the mold cavity, cooled and solidified;

Post processing:

cleaning the shell, cutting off the sprue and riser, sandblasting or machining to finish the surface, efficient process, suitable for mass production of precision small and medium-sized parts.

Please upload files like drawings, material specifications, quantities, and shipping destination.